A pioneering new building method that could deliver carbon-free energy to stations along Britain’s new high speed rail network is being trialled at an HS2 construction site.

Ground heat will be harnessed through the foundations of a newly built construction site office, with the technology estimated to gather – by civil engineering experts, Keltbray – enough energy to supply 80% of the building’s heating and hot water.

Euston and Curzon Street station in Birmingham could be the first to benefit from the new zero-carbon renewable energy technology, as engineers continue to explore the new piling method known as HIPER* pile.

“The innovation combines a number of novel technological breakthroughs to deliver the first major change in the piling industry for over 70 years. HIPER Piles use zero-cement concrete, halving embedded carbon emissions compared with traditional methods” explained Keltbray Technical Manager, Asha Panchal.

The eco-friendly technology takes advantage of a new piling technique that swaps solid concrete foundation piles for recyclable hollow ones, created from a steel industry waste product that lowers the carbon-intensive cement content by up to 70%.

The Technical Manager continued, “the fact that HIPER piles are hollow also means that they are 60% more thermally conductive so they can harness the earth’s natural zero-carbon thermal energy more efficiently than conventional solid thermal piles.”

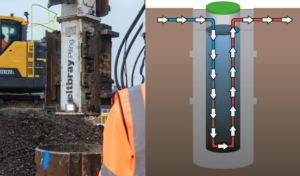

How it works

As part of the site office’s foundations, hollow tube piles – structural supports used to support the foundations of a building or structure – are bored up to 25 metres into the ground. They are then filled with water, before pipes carrying cold flowing water to and from the building above are run through each pile cylinder.

As the ground’s heat warms the standing water in the cylinders, heat is transferred to the pipes and carried to the surface to supply the building’s heating system.

During the summer months, the technology can also be reversed and used like air conditioning to cool the building by transferring heat back into the ground, further increasing sustainability by both reducing costs and pollution.